Smart Manufacturing: A Guide to Automation and Efficiency

Smart manufacturing is the use of digital technologies to improve the performance of manufacturing operations. This includes the use of automation, data analytics, and artificial intelligence to optimize production processes, reduce costs, and improve quality.

There are many benefits to smart manufacturing. These include:

- Increased productivity: Smart manufacturing can help to increase productivity by automating tasks that are currently done manually. This can free up workers to focus on more strategic tasks, and it can also help to reduce errors.

- Reduced costs: Smart manufacturing can help to reduce costs by optimizing production processes. This can be done by identifying and eliminating waste, and by improving efficiency.

- Improved quality: Smart manufacturing can help to improve quality by monitoring and controlling production processes. This can help to ensure that products meet specifications, and it can also help to identify and prevent defects.

There are many different technologies that can be used for smart manufacturing. These include:

- Automation: Automation is the use of machines to perform tasks that were previously done by humans. This can include robots, conveyor belts, and other equipment.

- Data analytics: Data analytics is the use of data to identify trends and patterns. This data can be used to improve production processes, optimize resources, and make better decisions.

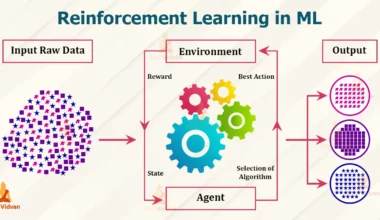

- Artificial intelligence: Artificial intelligence (AI) is the ability of machines to learn and make decisions. AI can be used to automate tasks, improve decision-making, and optimize production processes.

There are many different ways to implement smart manufacturing. The best approach will vary depending on the specific needs of the manufacturing operation. However, there are some general steps that can be followed:

- Identify the goals of smart manufacturing: What do you hope to achieve by implementing smart manufacturing? Do you want to increase productivity, reduce costs, or improve quality?

- Assess the current state of your manufacturing operation: What are your current processes? What are your current challenges?

- Identify the technologies that you need: What technologies can help you to achieve your goals?

- Implement the technologies: This may involve installing new equipment, changing your processes, or training your employees.

- Monitor and evaluate the results: How have the new technologies affected your manufacturing operation? Are you achieving your goals?

Smart manufacturing is a complex and evolving field. However, the benefits of smart manufacturing are clear. By using digital technologies to improve production processes, manufacturers can increase productivity, reduce costs, and improve quality.

Here are some specific examples of how smart manufacturing is being used to improve manufacturing operations:

- The automotive industry: The automotive industry is one of the early adopters of smart manufacturing. Many car manufacturers are using robots to automate assembly lines, and they are also using data analytics to optimize production processes.

- The food and beverage industry: The food and beverage industry is another industry that is benefiting from smart manufacturing. Many food and beverage manufacturers are using sensors to monitor the quality of their products, and they are also using data analytics to optimize their supply chains.

- The electronics industry: The electronics industry is also using smart manufacturing to improve its operations. Many electronics manufacturers are using robots to assemble components, and they are also using data analytics to optimize their manufacturing processes.

The future of smart manufacturing is bright. As digital technologies continue to evolve, manufacturers will have even more opportunities to use smart manufacturing to improve their operations. This will lead to increased productivity, reduced costs, and improved quality.

If you are a manufacturer, I encourage you to learn more about smart manufacturing. There are many resources available to help you get started. The National Institute of Standards and Technology (NIST) has a website dedicated to smart manufacturing, and there are also many industry associations that offer resources and training.

The future of manufacturing is bright, and smart manufacturing is a key part of that future. By embracing smart manufacturing, manufacturers can improve their operations and stay ahead of the competition.thumb_upthumb_downuploadGoogle itmore_vert